As a guitar tech for years, I’m always interested in how someone has their instrument set-up. Most of my guitars are set up w/action @ the 12th fret about 5/64" E and 3-4/64" e. I run a little less than .010 relief @7, with low action@ the nut.

Just wondering how ya’ll run yours.

Steve

Action

Hey Steve,

I am set up pretty similar. The ones I have tweaked to my liking are around 5/64 on the low E. One guitar is a hair under. I get my nut down to minimums (and occasionally to my consternation, sometimes a tad less). The relief used to typically be in the 5 to 7 range, although I don’t generally measure it any more. When I start the setup I start with it flat and add relief as necessary, so relief is more of a feel and eyeball kind of thing. I have one guitar that is about 6/64 (3/32) on the low E, but I haven’t done any setup on it yet. It has a T-Bar instead of an adjustable truss and I am still waiting for it to settle in a bit. It came pretty nice from the factory. I like the way it plays and sounds and am a bit wary to mess with it. At some point, I’ll lower the nut slots and see where that leaves everything.

Yea. That’s the way I do relief also. I can’t for the life of me get a feeler gauge on a radiused fret, and I’m a machinist  .

.

I need to pick up something to measure my action more accurate. Do you guys use a caliper or some type of ruler?

I haven’t messed with the action on my D-28. It came set up decent, but who doesn’t want it just a little lower?  The main problem with that is the fixed saddle and having to sand it down from the top. I’m way too chicken for that. I took some pics of the neck looking from the nut towards the bridge (they came out bad) and the neck seems pretty flat and the fret board looks like it lines up with the top of the bridge.

The main problem with that is the fixed saddle and having to sand it down from the top. I’m way too chicken for that. I took some pics of the neck looking from the nut towards the bridge (they came out bad) and the neck seems pretty flat and the fret board looks like it lines up with the top of the bridge.

I’m pretty happy with it except for playing above the 7th fret. Gets hard to play clean up there with medium action. Seems like every great player I’ve seen has their guitar set up with the strings as low as possible, I mean right on the fret board.

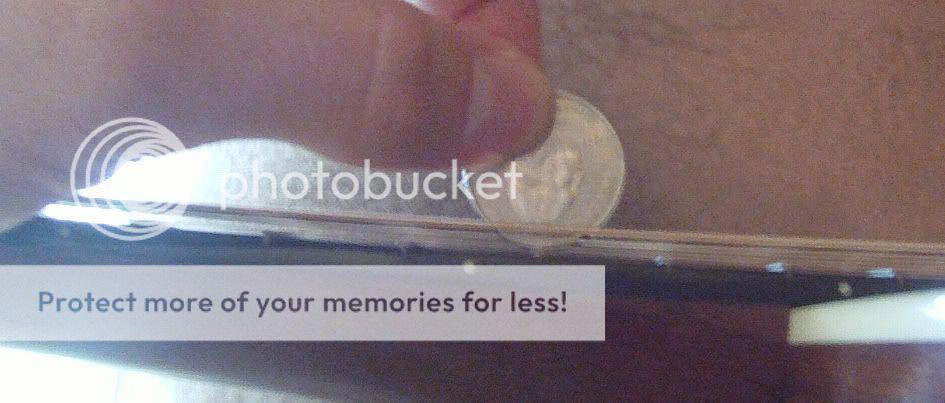

Here’s a couple pics. Sorry about the quality.

— Begin quote from "TNTaylor414"

Do you guys use a caliper or some type of ruler?

— End quote

For viewing/measuring relief, just put a capo on the first fret and depress the string at the 13th fret. The string serves as a great straightedge. As SMS the machinist said, it’s hard to get a very accurate reading, but you generally would gauge it or eyeball it at the 7th fret.

For measuring action, the best thing I have found is a cheap little 1/64 inch scale ruler with a little sliding “T” on it. You can use the little “T” to pretty accurately see the action height by rocking the ruler back and forth on the fret and viewing from the side. The little “T” makes it easier to see wen you are higher or lower than the bottom of the string. I can’t get feelers in there accurately.

Here’s some Martin specs (I’m looking them up in Dan Erlewine’s book)

Max relief on 7th to 9th frets: .010

String height at 12th fret: bass E: 3/32 min to 7/64 max

on the treble E: 1/16 min 5/64 max

String height at the nut, measured from the bottom of the string to the top of the first fret Bass E: .024 max, Treble E .016 min (I never set the nut using measurements, but that minimum on the treble seems kind of odd to me)

I pass those along for reference, as you can see, there is quite a range of acceptable (per Martin) action adjustments. The bass E of 3/32 is nice action, but when I can get a bit lower without buzzing, I’ll do it. 7/64 is pretty high, and based on your picture with the quarter on the fret, I would guess you are lower than that. On the flip side, I think it could be likely be set lower. I take it you have a glued in saddle. I would first look at the nut and your relief. You may be able to have the nuts slots lowered a bit. Almost all factory setups I have seen have the nut set kind of conservatively. Once I get the nut set well and the relief to where it’s just barely buzz-free, I am generally pretty happy. Even if I don’t have a glued in saddle, I do as much without losing saddle height as I can. At some point, as the saddle gets lower, volume and tone starts to fall off.

TNT,

Is your saddle the long one, glued in? The only way I sand those is w/a radius sanding block. I always tape everything off,and to put the radius back on the crown I use a fret file.

I’m tweaking a Taylor 414ce-LTD 2011 now.I had to do a little fret work, and I’m on the 3rd set of different strings right now.

D’Addairo EXP PB sound a little dull. The 80/20s sound better, and the bone saddle is definitely better than Tusq on this one.

My next step is a tighter fitting bone saddle built for this guitar, and maybe a little more neck angle.There is a definite sweet spot on the neck angle, and Taylor’s factory spec ain’t always it.

Steve

Oh Yea. If you go too low w/the saddle it’s router time.

Steve

Thanks Mike!

I’ve heard of the the capo 1st fret and hold down on the 13th and slide a business card under the 7th to measure relief, but I haven’t done it on this guitar…yet. I’ll try to pick up a 1/64 inch “T” ruler so I can get a good measurement at the nut. Reckon I can find one at Home Depot?

I thought your D-18GE had a glued saddle too Mike?

— Begin quote from "S MS Picker"

Oh Yea. If you go too low w/the saddle it’s router time.

Steve

— End quote

You mean trying to get a glued saddle out or taking off some of the bridge?

Yep, the saddle. I have a jig to use w/my Dremel. It clamps to the guitar top, and the router base fits in it. I rout until the material on the sides is thin enough to flake off. I also usually clean the bottom of the slot also so that I’ll know it’s good and flat(usually about .005" is more than enough). On several older Martins, I’ve I’ve widened the slot to get much better intonation.

I practiced on an old Yamaha. I’d rout a saddle out, and glue another in. Probably did this 6/7 times before I did my first Martin. That was in 1993 if I remember right.

Steve

The rule I use is a cheap 3/4" machinist rule. Bout $2.00. Fits perfect across 11 & 12, or 12 & 13.

Steve

— Begin quote from "S MS Picker"

TNT,

Is your saddle the long one, glued in?

— End quote

Yeah, it’s got the long glued saddle. It’s a d-28 Marquis so it’s got the old specs I guess. When I got the guitar it had notches in the saddle at the high E, B and G string. Looks like somebody tuned it to pitch with the strings in different places leaving two notches for each of those strings. I’d like to at least get those sanded out. I’ve heard some horror stories about our local authorized Martin tech though.

— Begin quote from "TNTaylor414"

Reckon I can find one at Home Depot?

— End quote

I suspect so. I don’t know where I got mine, but it wasn’t a specialty shop or anything.

— Begin quote from "TNTaylor414"

I thought your D-18GE had a glued saddle too Mike?

— End quote

That’s correct. I also have an OM-18 with a glued in saddle. Luthier Brian Kimsey has a method to heat and remove them that he detailed online. Thankfully, I have never needed that. Most people cut or rout them out. If the saddle is too short anyway, them there’s no strong reason to try to preserve it. However, I thought I’d mention it just in case. If anyone ever needs a link to that, let me know and I’ll go hunt it down.

— Begin quote from "S MS Picker"

TNT,

I always tape everything off,and to put the radius back on the crown I use a fret file.

— End quote

Steve, that’s a great idea to use the fret crown file. I’ll have to remember that. I’ve always worked it by hand.

Hey Steve,

I am guessing you have the Stew-Mac Dremel router base? I got one of those (and love it), but I don’t have the saddle slot jig. It looks slick, but I haven’t had an absolute need. It would be nice to be able to square up the slots. Is it pretty foolproof (that would be me-proof)?

Mike,

The jig works great. Your Dremel bearings have to be tight/new to get the best possible, true cut. The end mills are important also.I used industrial,very high quality end mills so the cut requires very little cleanup.

I got this one mainly to true the slot for UST installation and to correct intonation on 70’s and 80’s guitars. I’d widen the slot enough to compensate the b and sometimes the E.

Haven’t done one in years, so I’d have to practice some .

Steve

Thanks Steve,

I am pretty sure I’d need a new Dremel. It does fine for routing edges, but the forces are always in one direction with that.

One of the best deals I ever found to go with the Dremel router was a bunch of assorted carbide dental bits. It was like $15 bucks for maybe 50 of them. I think I got them from Grizzly (or maybe northern tool). I also got a few spiral routing bits from Stew-Mac specifically made for it, but the cheapie assortment has proven to be very useful. I have used them on all sorts of material. If you are interested, let me know and I’ll figure out where I got it and if they can still be purchased.

Remember that nice D-28 Marquis and D-18GE, that you guys have, have very nice fossilized ivory nuts and saddles. My advice is to find the string gauge you like, find a good luthier and get a professional set up. Then get your measurement tools and record where the action is. Stew-Mac has a very useful “String Action Gauge” where you can measure the action at the 12th fret nice and easy.

KGM, thanks for the head’s up. I bought my GE used. The saddle is still the fossilized ivory, but I am not convinced about the nut. It could be, but if I was forced to guess, I think it’s bone. Apparently some GE owners prefer bone and swap them out. I have played some GEs that were new (and thus had the stock ivory), and I like they way they sound right out of the box. At any rate, I have the GE tweaked to my liking, so hopefully it will stay stable for about another 50 years. I don’t ask for much.